Blastox One Step vs Lead Remediation Coating Technologies

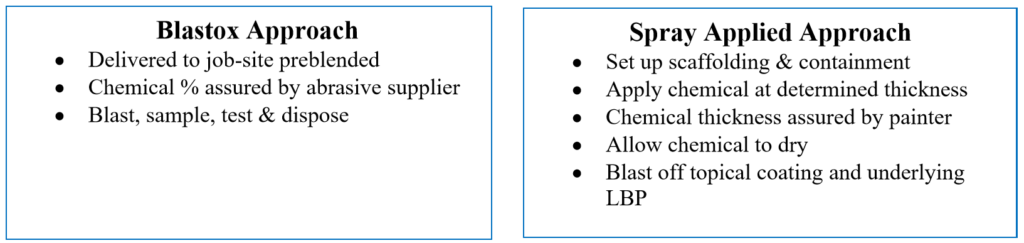

When our industry is required to deal with lead paint abatement, there are 2 general approaches that are used to ensure the elimination of hazardous lead paint waste. An easy and cost-effective way is to purchase Blastox® blended abrasive and have it delivered to the job site, ready to blast. Here, the contractor would take the preblended abrasive and blast clean the surface, similarly to other blast & paint projects. The Blastox® approach is called “One Step Lead Abatement” as it does not require additional application steps like other lead remediation coating technologies.

The other general approach to lead abatement requires multiple steps. First, you will need to set up scaffolding and containment. This will allow you to apply the chemical on all areas and help ensure overspray doesn’t migrate off the property causing issues. After setting this up, you will need to paint (spray, roller) the chemical on to the lead paint at some yet to be determined thickness between 20 – 40 mils. Then, you’ll need to let it dry and hope that you have uniform thickness throughout the painted surface.

With lead remediation coating technologies, you risk having areas that contain no, or less than sufficient amounts of chemistry to render the lead paint waste non-hazardous. Finally, you will need to blast & remove not only the lead-based paint, but also the topical chemical coating of between 20-40 mils that you applied to stabilize the lead. This will result in additional abrasive and labor expenses to remove the additional coating, plus the expense of additional abrasive disposal.

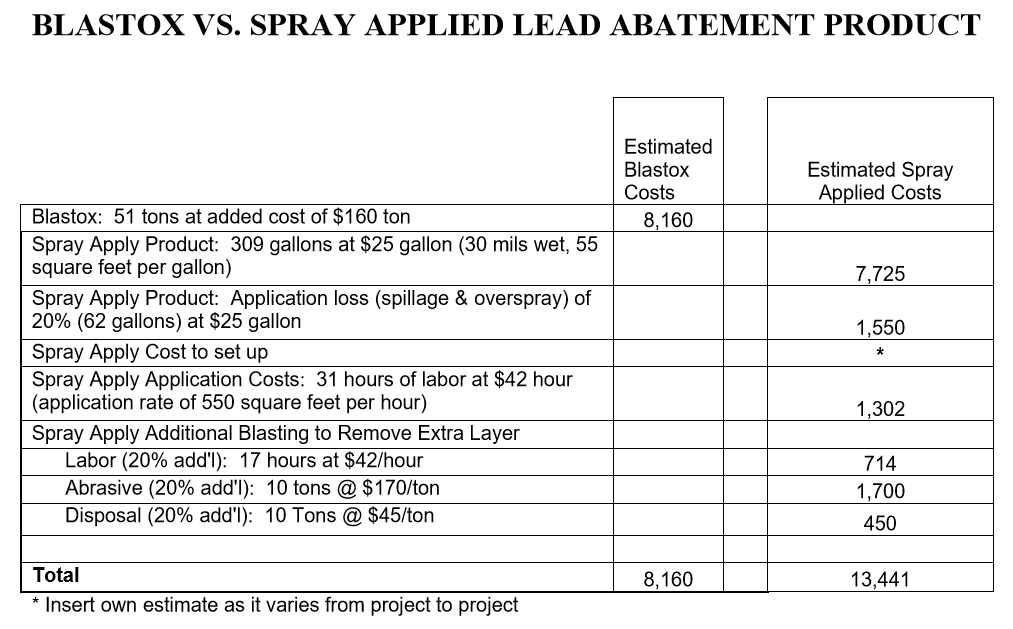

As the table below illustrates, Blastox® is a more cost-effective approach than any of the lead remediation coating technologies. The chemistry has been tested by EPA, FHWA and US DoD, and has been proven to be long-term stable. That assures peace of mind and reduced liability for stakeholders.

There is no mixing, metering or additional application steps needed at the job site when using this technology. Also, you will not incur additional labor costs that other lead paint abatement techniques require. The spent abrasive waste can be tested via TCLP to classify the waste as non-hazardous once blasted.

Blastox® has been used to successfully stabilize over 150,000,000 square feet of lead based paint. This success is owed to the One Step application of Blastox®. Since its available pre-blended, it is ready for application once the blended media reach your job-site compared to the multiple step approach of lead remediation coating technologies.

TECHNICAL BULLETIN

- Determining Proper Blend Ratios

- Use With Recyclable Abrasive

- Comparison With EPA Leach Protocols

- Long Term Stability Test Data

- Coating Performance Test Data

- Ecoquip Compatability

- Blastox vs Spray Apply Products

- The Proven Solution for Waste Stabilization

- Blastox Wins Technology Transfer Award

- Land Disposal Restrictions for Spent Abrasive

- EPA Confirms Long Term Stability of Blastox